Overview

Being a prestigious and conspicuous part of it’s business, a national retail brand sought to guarantee the continuous power supply of it’s flagship Oxford Street store. As well as overcoming access limitations, due to installation six floors above the store, Shenton Group provided a backup generator solution working as a peak lopper to enable the store to cope with the high electrical demands of peak periods on one of Britain’s busiest shopping streets.

Problem

A continuous power supply is an increasingly important priority, especially for a brand’s flagship store. Being continually in the limelight and providing a continually high turnover of stock to a constantly high footfall, flagship stores simply cannot afford the potential damage to reputation and trade that mains power supply outages would bring. With the UK’s mains power supplies becoming increasingly uncertain as the National Grid closes more and more dated coal power stations faster than it can introduce greener replacements, the probability of blackouts poses a greater threat as National Grid reserve power supplies drop to their lower in recent years.

Although standby generator installation projects are usually relatively straightforward, the client’s premises meant that the standby generator had to be installed on the 6th floor of the building, accessed only by lift. In addition, the fuel tanks required locating some distance away within the sub-basement which also had the same access limitations.

Shenton Group’s Technical Director, Derek Barry confirmed the unique challenges that the project posed to Shenton Group: “As well as limited access space available to transport and install the generator, diesel tanks had to effectively and safely supply the generator from 60 metres away in the buildings sub-basement”. Derek added: “In addition to the logistical challenges, the work had to be completed by the time the store introduced extended opening hours in order to cope with a forthcoming, large national sporting event”.

Solution

Shenton Group was contacted to find a solution after Powell Electrical Services found it difficult to source a provider to complete the project to the strict client requirements. Shenton Group’s Derek Barry elaborated: “Not only did the work have to be undertaken to meet a narrow timeline, but it had to be carried out whilst this busy store was operational”.

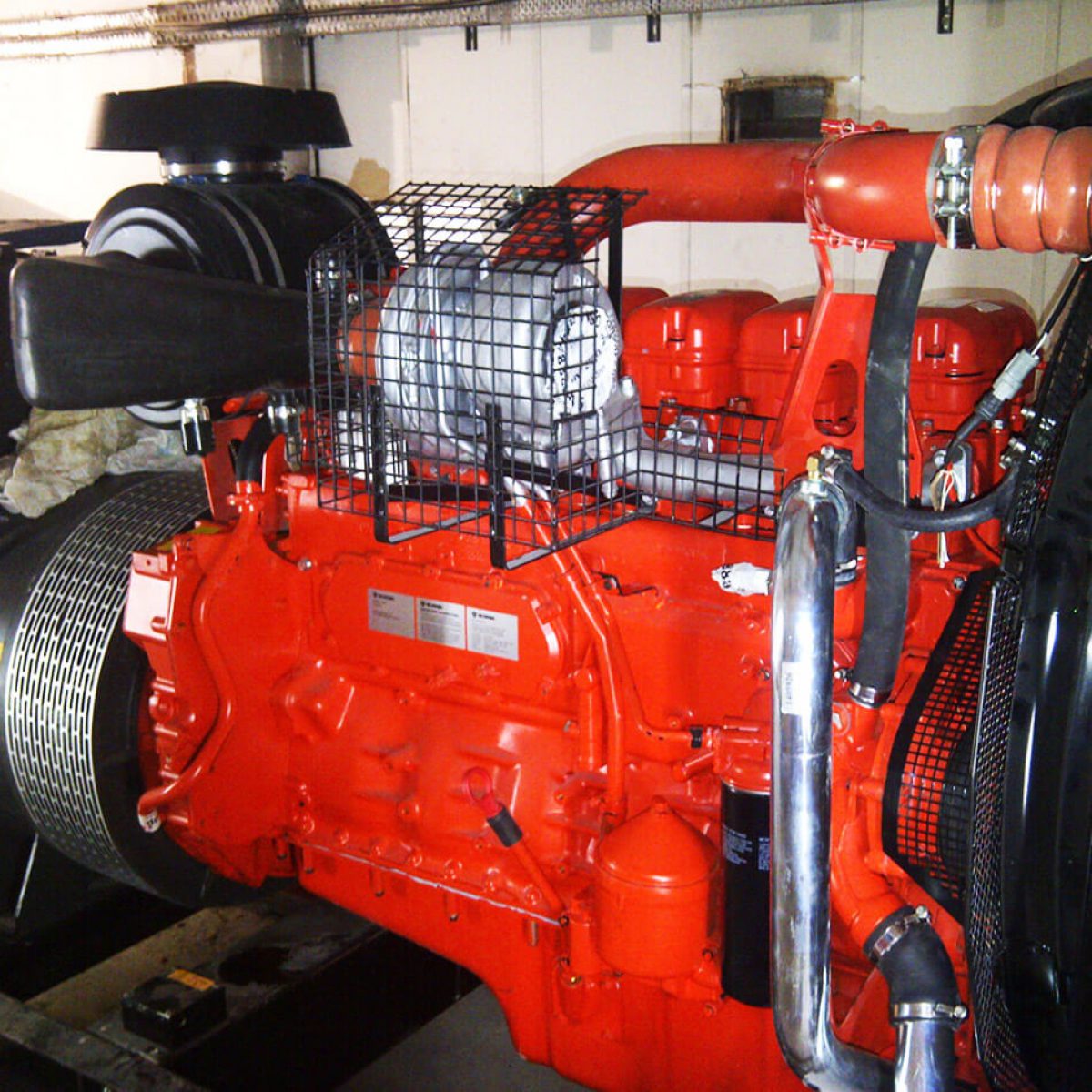

Because the only viable location for the generator to be installed was on the 6th floor of the building, in an area that can only be accessed by lift, a number of scenarios were considered to aid installation. Derek Barry explained: “One scenario examined was to crane the generator in through the roof of the building. However, being one of the UK’s busiest shopping streets, this would cause too much disruption to the busy Oxford Street store”. Derek continued: “The solution we arrived at was a complete strip down of the generator engine. The engine and alternator were taken apart so that all elements of the 8 tonne generator could fit into a lift 850mm x 950mm, with a load capacity of just 600kgs. This meant around 15 trips just to get the generator to its location on the 6th floor”.

To fuel the generator, 7 bespoke fuel tanks were made to fit the lift capacity to deal with the access issues to the sub-basement. In order to provide their contents to the generator, Shenton Group installed over 60 metres of fuel pipe.

Delivery of the generator had to be out of hours to prevent any loss of revenue to the store. To meet this requirement, delivery and installation was scheduled from 10pm – 3am and had to be completed within this short window of time. 9 engineers worked on the installation.

The generator solution also acts as a ‘peak lopper’ to enable the store to deal with the high electrical demands of peak periods. Otherwise known as peak shaving, the generator is synchronised with the building’s mains power supply to always deliver enough power to meet demand that cannot always be met by the mains power supply.

Outcomes

Shenton Group provided the client with an innovative solution to installing their standby generator and fuel tanks in extremely space-limited areas, over six floors apart. Despite the challenges of working through the night in a dusty building site with temporary lighting, no vehicular access and 12 flights of stairs, the generator was installed and the overall project was completed on time.

The work was undertaken without any interference with store’s opening times, nor trading and the company is now guaranteed continuous power, regardless of whether National Grid supplies are sufficient or not, thanks the the generator acting as a peak lopper.

About Shenton Group

Shenton Group is the UK’s leading technical expert in standby power, uninterruptible power supplies, and combined heat and power supplies. The company provides power solutions to organisations spanning a broad array of industries that rely on continuous power supplies and includes; finance, telecoms, healthcare, IT, manufacturing, retail, education, government, utilities, and sport and leisure.

Shenton Group’s standby generator range includes single and three phase generator solutions, ranging from 10kVA to 3.2MVA. Being British built to the highest quality and safety standards, Shenton Group generators are ideal for use as prime power or standby power supply usage. All Shenton Group diesel generators include; a full range of weatherproof canopies to meet sound attenuation levels; proven industry-leading control systems and switchgear hardware; integral bunded base-frame fuel tanks and fuel management systems; containerised modular solutions; custom built drop-over acoustic canopies; and skid-mounted ‘open’ sets for specific applications.

Shenton Group provides a range of DEFRA-approved bulk fuel tanks, including plastic fuel tanks and double-skinned steel fuel tanks. Polyethylene bulk fuel tanks are maintenance-free, fully-bunded and are OFTEC and DEFRA certified. They are available in capacities ranging from 1220 litres to 5000 litres. Shenton Group’s steel bulk fuel tanks are purpose built and double-skinned. They are manufactured to BS799 part 5 and comply to both statutory pollution prevention PPG2 and DEFRA regulations.

Generators can also be configured to provide ‘Peak Lopping’, otherwise known as ‘Peak Shaving’, to provide additional power when mains supplies cannot deliver enough power to meet peak demands. Shenton Group can configure generators so that they use the most cost effective mains power, but provide added support to reinforce mains power during periods of high demand. Peak lopping is required when a facility runs out of power, rather than making standby provision for power failure.