Generators are an essential asset in maintaining a stable power connection to your business and residential properties. Often hailed as a lifeline, they provide crucial support in case of a mass blackout or power loss.

In this article, we will provide a basic guide on how generators work, explain the different types of generators, and how you can ensure you find the right generator for you and your needs. Firstly, let’s look at what generators are:

What are Generators and What Do They Do?

If your mains power supply goes down, diesel generators are the perfect solution to supply power when it is needed, but they can also be used as a permanent power solution. Generators are complex machines that work by converting mechanical or chemical energy into electricity by capturing kinetic energy (the power of motion) and turning it into energy.

Industrial generators can be used as a primary power source in places where the local electrical grid is unavailable or difficult to access, such as mining and farming operations, new developments, and remote locations. These industrial generators are also frequently used to supply backup power to buildings, businesses, or homes during power outages. Generators can also be temporary, portable power solutions or permanent installations.

Shenton group typically supply diesel engine generator systems as standard. The UK has a very well-developed power grid, which remains stable for much of the time therefore most of the generator installations in the UK are for standby use or for legislative purposes such as life safety applications. Diesel generators are ultimately the most cost-efficient and beneficial solution for emergency standby power. The plethora of reasons why diesel generators are required include equipment malfunction, switchboard failure, transformers failure, network faults, transmission distribution faults on the network as well as to support renewable systems.

How Does a Generator Work?

Most generators run on some form of fossil or gas-based fuel, such as diesel, petrol or natural gas. The internal combustion engine will then run on the provided fuel source and in the process spin an alternator which creates electricity.

The Different Components of A Generator

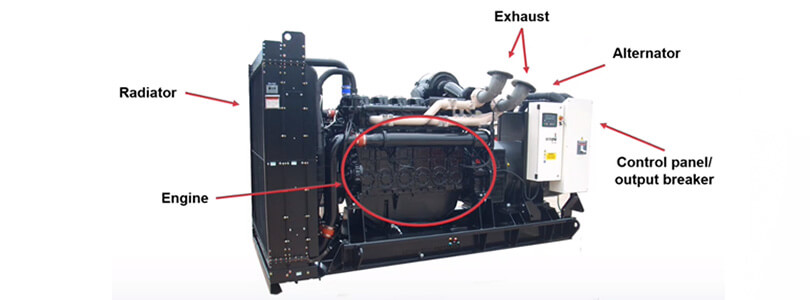

There are many components that help make up a generator.

Below, we have listed the different components that make up a generator and what their function is:

- Engine– the engine is the main component of a generator and as it runs it rotates the alternator rotor.

- Radiator: The radiator is used to cool the engine as it runs and keeps it from overheating

- Exhaust: A generator set includes an exhaust system that collects hot gases from engine cylinders and discharges them as quickly and silently as possible.

- Alternator: The main function of an alternator is to convert mechanical power to electrical power. Alternators consist of a steel housing containing the main stator and the rotor assembly. In a process called magnetic induction, the engine rotates an electromagnet rotor, inside the stator to produce an electrical current through copper wirings. Essentially, the engine drives the rotating shaft and turns the rotor which then produces electricity.

- Control Panel: In layman’s terms the control panel is the brains of the generator. There are various types of control systems but in a gist, they enable effective monitoring, and control and provide diagnostics to ensure the generator set operates within safe parameters.

- Output Breaker: this is the main switch where the power coming from the alternator can be connected to and provides protection against overload and electrical faults.

Generator Ratings

Specifying a generator can be a daunting task as it involves multiple points of consideration to be able to select the correct solution. There are three main types of generator ratings that are commonly referred to and these are explained below:

- PRP or Prime Rated Power

- COP or Continuous Rated Power

- ESP or Emergency Standby Power

Prime Power Generators (Prime Rated Power)

Prime Power generators are commonly used as the main source of power on building sites and events but also in the life safety, industrial and construction industries. Sites where a reliable main power source is needed external from the mains or National Grid, would also benefit from having a Prime rated generator access. Average power output should be 70% of the prime rating over 24hr period with unlimited allowance on hours of use. In times of peak demand, the generator would work on 100% of prime kW rating with 10% overload capacity for emergency use for a max of 1hr in every 12 hrs of use.

Prime power generators are the preferable option in the UK for continuous use over other types of generator, especially when the load (demand for power) varies or overloading may occur. They provide a buffer for design teams because of the 10% overload capacity and the unlimited use capability.

Continuous Power Generators (Continuous Rated Power)

Although very similar to their prime power counterparts, these generators are designed to run continuously with 100% consistent load for unlimited hours. These generators are mainly used for remote projects off the main power grid, including mining, construction, and oil or gas works.

Standby Generators (Emergency Standby Power)

Standby generators are designed to support mains power in the event of an emergency, providing power to buildings or anywhere needing a backup power supply, such as hospitals and data centres. ESP rating is available for the duration of the emergency outage. The average power output should be around 70% of the standby power rating. It’s a rating based on a varying load with the limitation being 200 hr annually. Having a backup generator for your company means you are protected in case of a blackout. To ensure a fast response to an outage, a standby generator will run weekly self-tests to ensure it can respond quickly and run efficiently the next time it is needed.

How to Determine the Size Requirement of the Generator Set Properly?

Like the main utility supply, generators are not an unlimited source of power therefore loads need to be steadily applied to prevent an engine from shutting down. When the load is suddenly applied, there will be a transient deviation in the voltage and frequency. Smaller generators, below 100kva, tend to have a greater load acceptance capability. When applying or removing a load from a generator set, it has an impact on the quality of power being delivered. The extent of the impact would depend on a variety of factors however the most significant factor is the size of the load that is applied to the generator at any given time. Shenton group has the extensive technical capability within our highly experienced team to accurately advise our customers on the best generator set suitable to their unique circumstances.

Next, we explore the function that an ATS provides and how they interact with a generator.

Do I Need an Automatic Transfer Switch (ATS)?

Not necessarily, however, if you are using alternative sources of power, an ATS will automatically switch over from the main power source, reducing the need for manual switching between power supplies. An Automatic Transfer Switch provides a reliable means of automatically transferring load between the primary and alternative sources of electrical power, such as transferring from mains power to a generator.

Your power sources are continuously monitored by an automatic transfer switch. You won’t need to manually start the standby generator with an ATS, as it will start and stop as needed during a power loss. Using your generator becomes simpler as a result.

Within seconds of a power outage, an automatic transfer switch senses the loss of power, instructing the generator to start before transferring the electrical load to the generator to provide backup power. Once the main utility power returns, the ATS system transfers the electrical load back to the grid or main power source and signals the standby generator to shut down. The generator then returns to standby mode where it waits for the next outage.

Like the main utility supply, generators are not an unlimited source of power therefore loads need to be steadily applied to prevent an engine from shutting down. When the load is suddenly applied, there will be a transient deviation in the voltage and frequency. Smaller generators, below 100kva, tend to have a greater load acceptance capability.

Generator Rental, Purchasing & Maintenance

Whether you’re running a data centre, bank or hospital, power failures can be disastrous to your essential operations. Having a standby generator reduces the risk of power interruption, however, they will only be useful if they’re properly chosen, installed, and maintained.

At Shenton Group, we can provide services including generator hire, maintenance, installation, and servicing for combined heat and power solutions. If you’re thinking about renting or trialling a generator, please visit our generator rental section. If you need assistance in choosing and purchasing the right system for you, our power consultants can help.

Looking for Maintenance Support on a Generator?

To keep your investment performing at its best, we provide a variety of maintenance support contracts for every type of generator on the market. With every generator, UPS and CHP unit having consumable components, we recommend keeping them and your other power products in tip top shape with our maintenance and monitoring plans.

Please speak to us about our power products today – our team can help answer any questions you may have.